• HUMAN detection — 4 workers identified (0.54 - 0.76 confidence)

• jelly detection — drying surfaces tracked (0.92 - 0.98 confidence)

• background segmentation — environment separation

Humans: 4 | Items: 10

Figure 1: DRIFT processing a real factory scene — simultaneously detecting workers for safety monitoring and tracking multiple drying surfaces for quality assessment. Confidence scores shown for each detection.

The Value of Dehydrated Food

Food dehydration is one of the oldest preservation methods. It transforms perishable produce — lasting days — into shelf-stable products lasting months or years. Dried fruits, vegetables, fish, spices, and pulp products serve both domestic consumption and export markets.

The economics are straightforward: fresh produce has a short window before it spoils. Dehydration extends that window dramatically, reducing waste and enabling transport to distant markets.

But quality matters. Poorly dried products — with hidden moisture, uneven texture, or color degradation — spoil during storage, sometimes weeks after production. The difference between good dehydration and bad dehydration is consistent monitoring.

System Architecture

┌─────────────────────────────────────────────────────────────────┐

│ DRYING SURFACE │

│ (Fruit pulp, vegetables, fish, spices) │

└───────────────────────────┬─────────────────────────────────────┘

│

▼

┌─────────────────────────────────────────────────────────────────┐

│ CAMERA + SENSOR UNIT │

│ ┌─────────────────┐ ┌───────────────────────┐ │

│ │ High-Res │ │ Environmental Sensors│ │

│ │ Camera │ │ • Temperature │ │

│ │ • RGB frames │ │ • Humidity │ │

│ │ • 20+ FPS │ │ • Light Level │ │

│ └────────┬────────┘ └────────┬──────────────┘ │

│ │ │ │

└───────────┼──────────────────────┼──────────────────────────────┘

│ │

└──────────┬───────────┘

│

▼

┌─────────────────────────────────────────────────────────────────┐

│ EDGE AI UNIT │

│ ┌─────────────────────────────────────────────────────────┐ │

│ │ Pre-Processing │ │

│ │ • Color correction • ROI extraction • Noise reduction │ │

│ └─────────────────────────────┬───────────────────────────┘ │

│ ▼ │

│ ┌─────────────────────────────────────────────────────────┐ │

│ │ Feature Extraction │ │

│ │ • Color drift (ΔE/HSV) • Texture • Gloss • Edges │ │

│ └─────────────────────────────┬───────────────────────────┘ │

│ ▼ │

│ ┌─────────────────────────────────────────────────────────┐ │

│ │ Environmental Fusion │ │

│ │ • Temp correlation • Humidity adjust • Time context │ │

│ └─────────────────────────────┬───────────────────────────┘ │

│ ▼ │

│ ┌─────────────────────────────────────────────────────────┐ │

│ │ AI Inference │ │

│ │ • Moisture estimation • Dryness stage • Anomaly detect │ │

│ └─────────────────────────────┬───────────────────────────┘ │

└────────────────────────────────┼────────────────────────────────┘

│

▼

┌─────────────────────────────────────────────────────────────────┐

│ DECISION ENGINE │

│ ┌───────────────┐ ┌───────────────┐ ┌───────────────┐ │

│ │ ✓ READY | | ⏳ DRYING │ │ ⚠ ALERT │ │

│ │ Next layer │ │ Keep waiting │ │ Check needed │ │

│ └───────────────┘ └───────────────┘ └───────────────┘ │

└───────────────────────────┬─────────────────────────────────────┘

│

┌───────────────┴───────────────┐

▼ ▼

┌───────────────────────┐ ┌───────────────────────┐

│ WORKER INTERFACE │ │ DATA & TRACEABILITY │

│ • Display / alerts │ │ • Batch records │

│ • Per-surface status │ │ • Visual timeline │

│ • Simple signals │ │ • Quality export │

└───────────────────────┘ └───────────────────────┘

• Various camera angles and distances

• Different lighting conditions (sun, shade, overcast)

• Multiple product types and surface arrangements

• Worker positions and movements

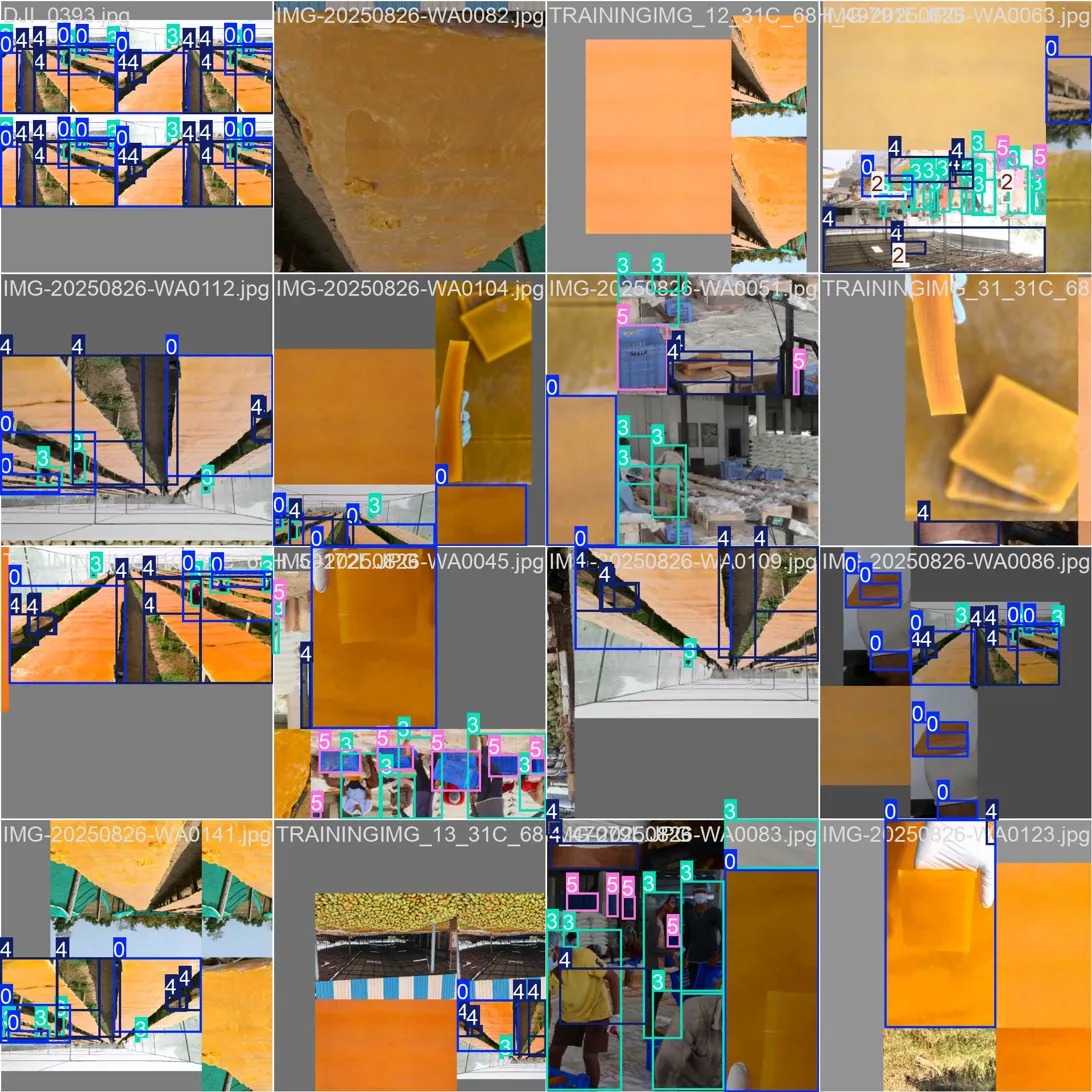

Classes: 0-jelly_sheet | 3-person | 4-wood_tray | 5-blue_tote

Figure 2: Detection results across multiple factory images — showing model performance in varied real-world conditions. Bounding boxes with class labels and confidence scores.

The Traditional Process

Food dehydration is one of the oldest manufacturing processes in India. Long before automation, quality was ensured by experience — workers visually judged moisture, color, and texture using instinct built over years.

In South India, traditional fruit pulp products are still made this way: pulp is poured onto surfaces, dried under the sun, and layered carefully over multiple days. This process produces texture and taste that many producers believe industrial dryers still cannot match.

But while the process has not changed, the environment around it has.

The Dehydration Workflow

- Prepare drying surface — clean, positioned for sun exposure

- Pour or spread product — fruit pulp, sliced vegetables, fish

- Distribute evenly across surface

- Wait for sun drying — 2 to 8 hours depending on product and weather

- Check if dry enough — continuous visual inspection

- If dry: add next layer or move to packaging

- If not dry: wait more, check again

- Repeat until complete

Step 5 is the bottleneck. Every other step can be scheduled or mechanized. But continuous visual checking requires sustained human attention — and that is where problems accumulate.

Why Visual Checking Is Difficult

Dryness assessment is not a binary decision. It is a slow, continuous physical process influenced by temperature, humidity, airflow, and surface thickness.

Human vision is good at spotting obvious wetness — but poor at detecting residual moisture, uneven dehydration, and early-stage anomalies. These errors accumulate silently and surface only during storage or shipment.

| Challenge | Why It's Difficult |

|---|---|

| Wet vs dry looks similar | Color difference is subtle, becomes visible hours later |

| Uneven drying | Center dries slower than edges, shade creates wet spots |

| Sustained attention | Continuous checking for hours is not practical |

| Scale | One person cannot monitor many surfaces accurately |

| Consistency | Different people, different standards, different results |

The Workforce Reality

This checking problem will become harder to solve with people alone.

- Workforce availability is changing — Younger, educated workers prefer roles that are not repetitive visual monitoring for hours.

- Experience is difficult to transfer — Skilled workers retire. Their judgment, built over years, is not easily documented or taught.

- Quality requirements are rising — Export markets and regulations increasingly demand batch-level documentation and consistency.

- Scale requires consistency — As operations grow, maintaining uniform quality across shifts and locations becomes harder.

The process works — but continuous monitoring is difficult without the right tools.

What DRIFT Does

DRIFT is not a camera. It is not a dashboard. And it is not a replacement for workers.

DRIFT is a real-time dehydration intelligence layer that continuously observes drying surfaces, detects subtle quality changes, and converts visual signals into actionable insights.

DRIFT IS:

- A continuous monitoring system

- A real-time decision support layer

- A way to capture expertise as data

- Designed for edge, scalable to silicon

DRIFT IS NOT:

- A replacement for workers

- A cloud-dependent system

- A guarantee of zero waste

- A one-time inspection tool

DRIFT gives objective signals — "too wet", "drying uneven", "risk of issues" — so workers can act earlier and more confidently.

How The Model Is Trained

Data Factory Image Collection

Images across drying stages — fresh, partial, complete, over-dried. Captured with temperature, humidity, and time metadata. Real conditions, real variation.

Labels Ground Truth from Experienced Workers

Workers with years of experience mark quality decisions. Their judgment becomes training signal. The goal is to capture expertise, not replace it.

Model Multi-Signal Detection

Computer vision for surface analysis. Color science (HSV, ΔE) for degradation tracking. Environmental fusion for moisture correlation. Image alone is not enough — context matters.

Validation Calibrated Accuracy

Estimates with confidence intervals. Known error bounds. Models are recalibrated seasonally to account for changing conditions.

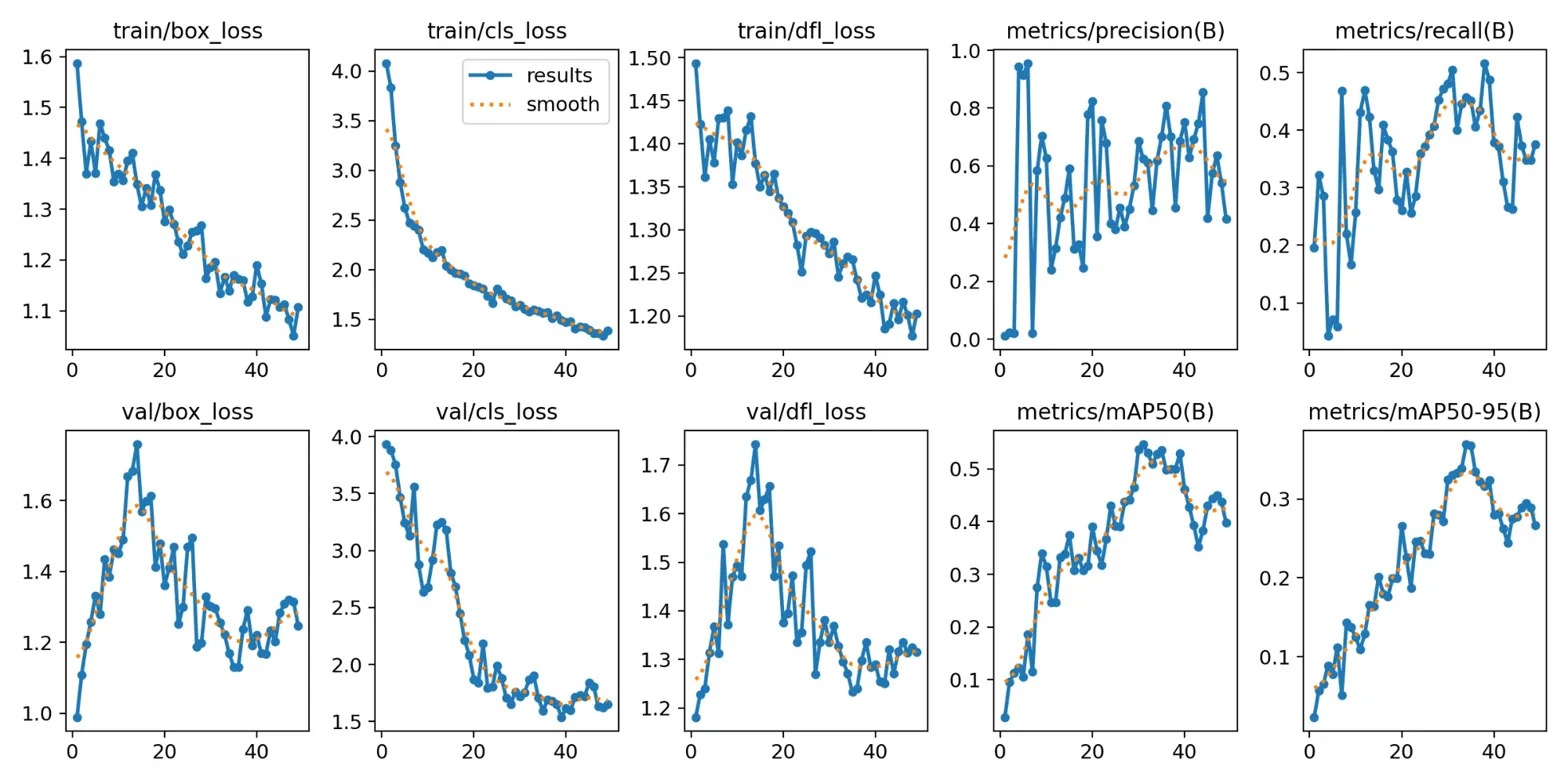

Loss curves decreasing over 50 epochs

mAP improving from 10% to 50%+

Validation follows training — no overfitting

Figure 2: Model training progress — loss decreasing, detection accuracy improving. Validation curves follow training, indicating the model generalizes to new images.

Technology Stack

| Component | Function |

|---|---|

| Camera + Edge AI | Real-time surface analysis at 20+ FPS |

| Color Analysis (HSV / ΔE) | Detect browning, over-drying, fresh areas |

| Moisture Estimation | Predict moisture level with confidence interval |

| Environmental Sensors | Temperature, humidity, light — adjust predictions |

| Decision Engine | Ready / Keep Drying / Alert logic per surface |

The architecture is designed to run at the edge — first on embedded systems, and eventually on dedicated silicon — enabling low-latency decisions without cloud dependence.

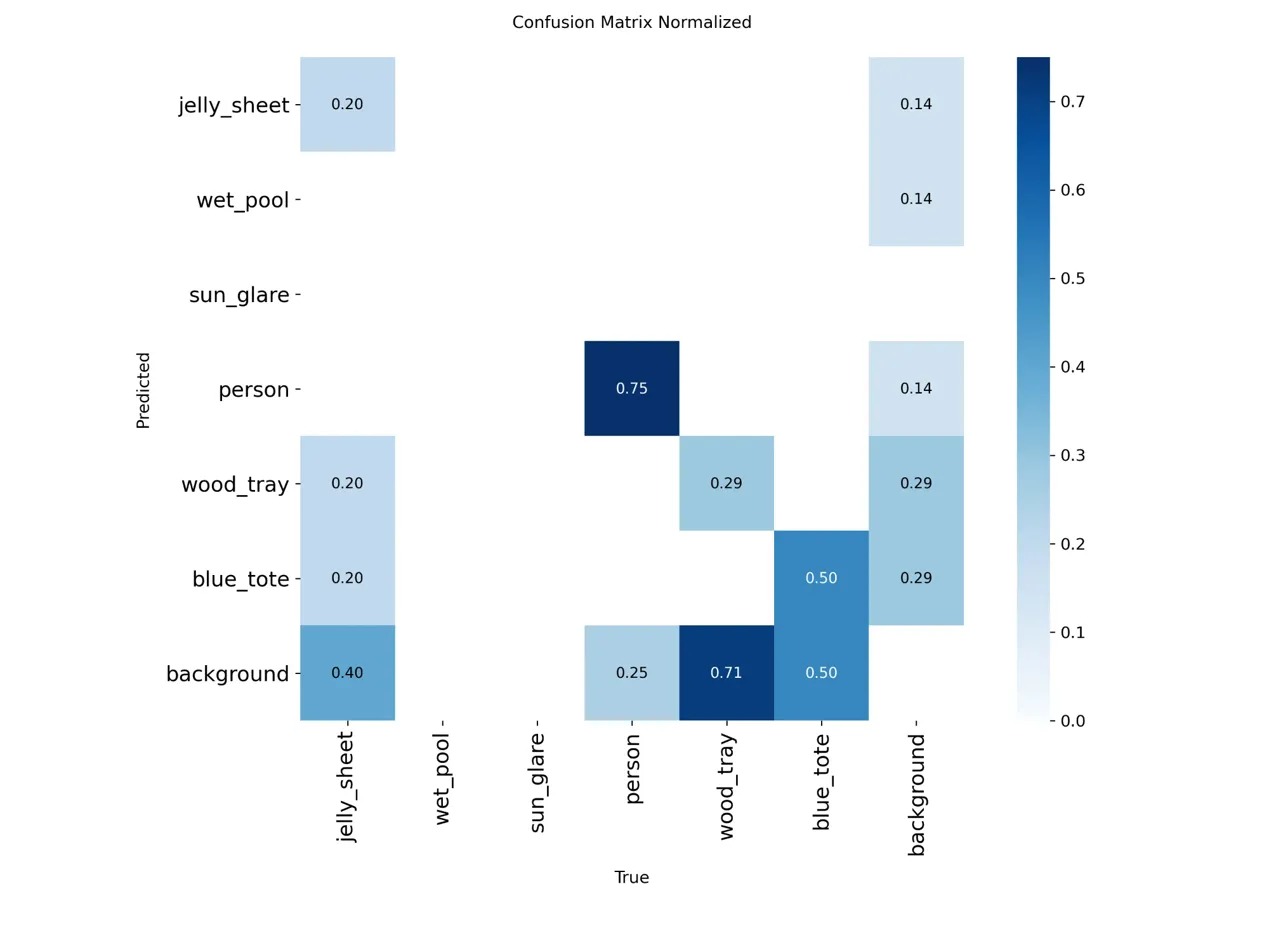

Person: 75% • Container: 50%

Transparent reporting of current state

Figure 3: Confusion matrix showing per-class detection accuracy. Person detection strong at 75%. Some classes need additional training data — reported transparently.

Current Limitations

DRIFT is a working system, not a finished product. Current limitations include:

- Calibration per product — Each product type (fruit, vegetable, fish) requires separate color and texture calibration.

- Controlled setup — Works best with consistent camera positioning and lighting conditions.

- Not a taste sensor — DRIFT monitors visual and physical signals, not flavor or aroma.

- Requires ground truth — Model accuracy depends on quality of training labels from experienced workers.

Target Products

| Product Category | Key Signal | Detection Approach |

|---|---|---|

| Fruit pulp / leather | Moisture between layers | Color + gloss analysis |

| Chilli, red spices | Over-drying, oil sheen | Red ΔE + texture |

| Turmeric, yellow spices | Brittleness, color fade | Yellow ΔE + crack detection |

| Banana, plantain | Browning, crispness | Color threshold + edge analysis |

| Leafy vegetables | Shrinkage, color loss | Green ΔE + area tracking |

| Fish, seafood | Spoilage indicators | Color anomaly + texture |

Path Forward

Over time, DRIFT evolves from a monitoring system into a core intelligence block — reusable across food processing lines, adaptable across products, and eventually manufacturable as dedicated hardware.

The hardest problems usually have the simplest solutions. In dehydration, the hard problem is sustained attention. The simple solution is a system that watches patiently and alerts when needed.

Summary

DRIFT does not modernize tradition by replacing it. It modernizes tradition by understanding it.

When intelligence observes patiently, automation becomes respectful. That is how traditional processes survive the future.